On QuantumScape's cell performance

Probably should go without saying that criticism from a competitor should be taken with a pinch of salt. But still, not for the first (or last) time @QuantumScapeCo spark debate with a showcase of their technology with only small-scale cells…

Now I’ve found these showcases very interesting so far, but I think the big problem is that they are presentations which would feel more at home at a battery conference, rather than the main vehicle for a public company communicating their progress to the public. And at the core of this debate are questions about what properties or performance attainable at single-layer credit card-size cell size (~0.1-0.2 Ah) can be scaled to automotive (»10 Ah). And this is an important Q for applied research where the answer isn’t always obvious.

There is also the shadow of any number of defunct startups that failed on this point. To their credit, QS show that they do get this, and have shared details (such as mAh/cm²) to alleviate worries about relevance in the absence of bigger cells, which other startups are showing. I think a single-layer, zero excess anode with a solid-solid Li/separator interface with >3 mAh/cm² certainly demonstrated in 2020 that QS have a system that shows great potential for a new cell chemistry that combines high energy, high cycle life, and fast charge.

In comparison with many past Li metal research papers (and companies) there isn’t too much scope here for fudging on cycle life and current density (e.g. with thin electrodes, lots of excess Li and electrolyte). Hence why many of us get very interested.

But one of the most common questions I see levelled at QS is on energy density, which they resist disclosing. And I see why, because on single-layer level, energy density does not matter - it’s not going to be great. What matters is the energy density of the final product.

And given the details we can hazard a pretty decent guess - I have done this a number of times before. The only important missing info is the separator thickness - I don’t really know why QS don’t disclose it, but Tim Holme at least hinted to #BMWS it’s “low tens of microns”. By my guesses that’s enough info for me to feel happy that QS are on track to hit >900 Wh/L, if they can scale to an acceptably large cell. We have seen hints of this at least, but not close to the final product, so manufacturing is still the big Q it was 18 months ago.

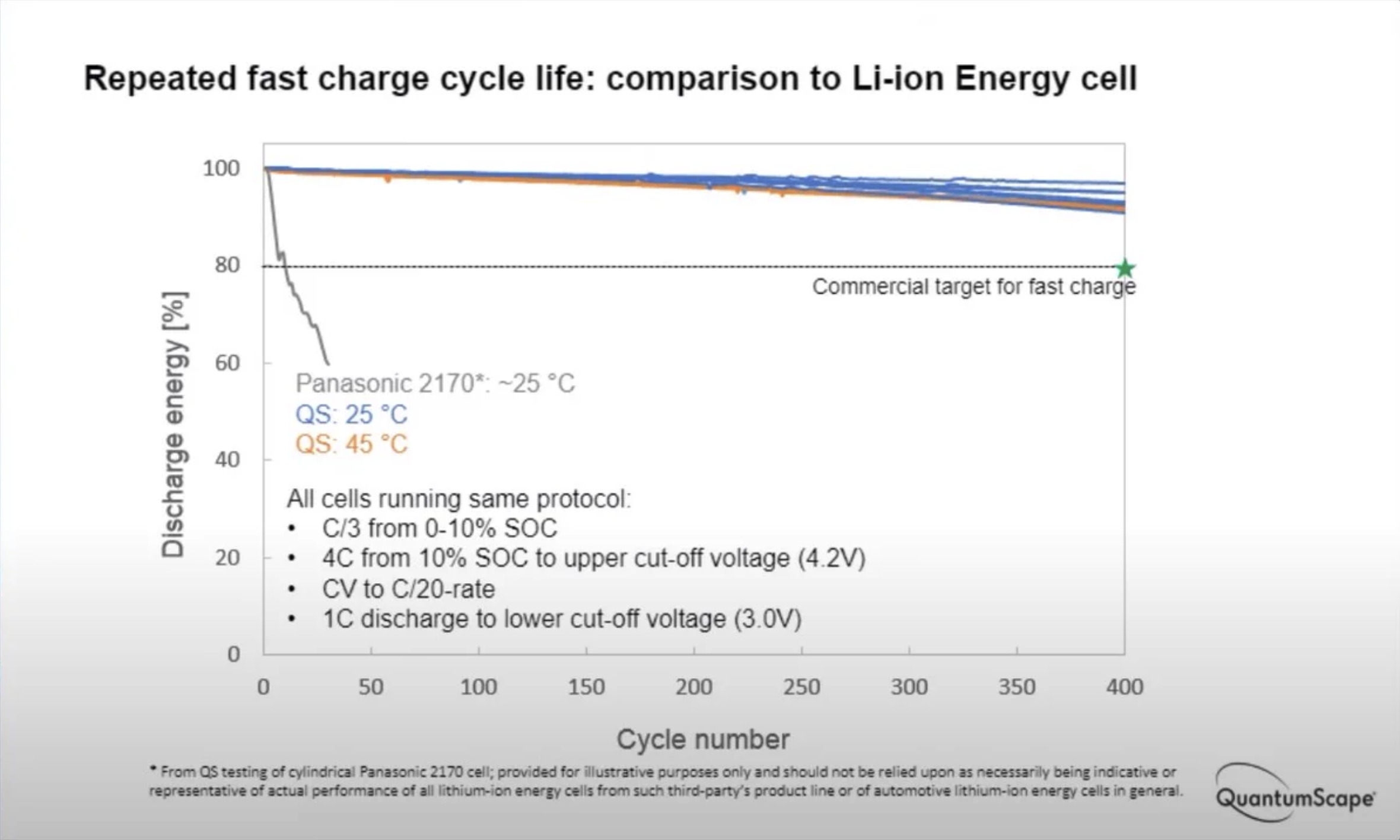

But, I digress - we were talking about fast charge. And in this respect there factors that scale non-linearly with cell size that we have to think about, e.g. thermal management. Any battery charged at 4C will start to get pretty warm depending on its internal resistance. A single layer cell might manage this ok, if it’s clamped between two big heat sinks. A cell with dozens of layers might not lose heat as efficiently and this could have significant consequences for how it degrades - not just Li but the cathode as well.

And in this respect I think QS have been making some slightly unfair comparisons, comparing with a 2170 cell more than an order of magnitude larger in capacity. If we want to talk fundamental mechanisms, a like-for-like single layer comparison would be a lot better.

And we can’t speculate that much on how the QS cell would fare with dozens of layers - we don’t know its resistance characteristics, thermal properties. And managing the heating can often be the bigger problem than the chemistry limitations themselves.

So while it’s interesting & encouraging to think about overcoming these chemistry related limitations, this risks feeling like a distraction from the main questions, and would be more effective to demonstrate in e.g. 10 layer cells they have shown already. And I think that not-quite-cricket comparisons like the above, and what I call “selective transparency” unnecessarily risks credibility. I would happily see more like-for-like comparisons with typical Li-ion, and if we’re going to get into the details and numbers, then share relevant ones - e.g. DCIR (in Ω cm²), and hopefully separator thickness??

comments powered by Disqus