Live-tweeting the Tesla Battery Day

Let’s see if Tesla Battery Day lives up to the high expectations. Assuming I stay awake I’ll add some of my takeaways in a thread here…

Lots of emphasis on a big rethink of cell manufacturing from the get-go - current processes aren’t scalable to get to the TWh level necessary, and to be able to reduce cost further.

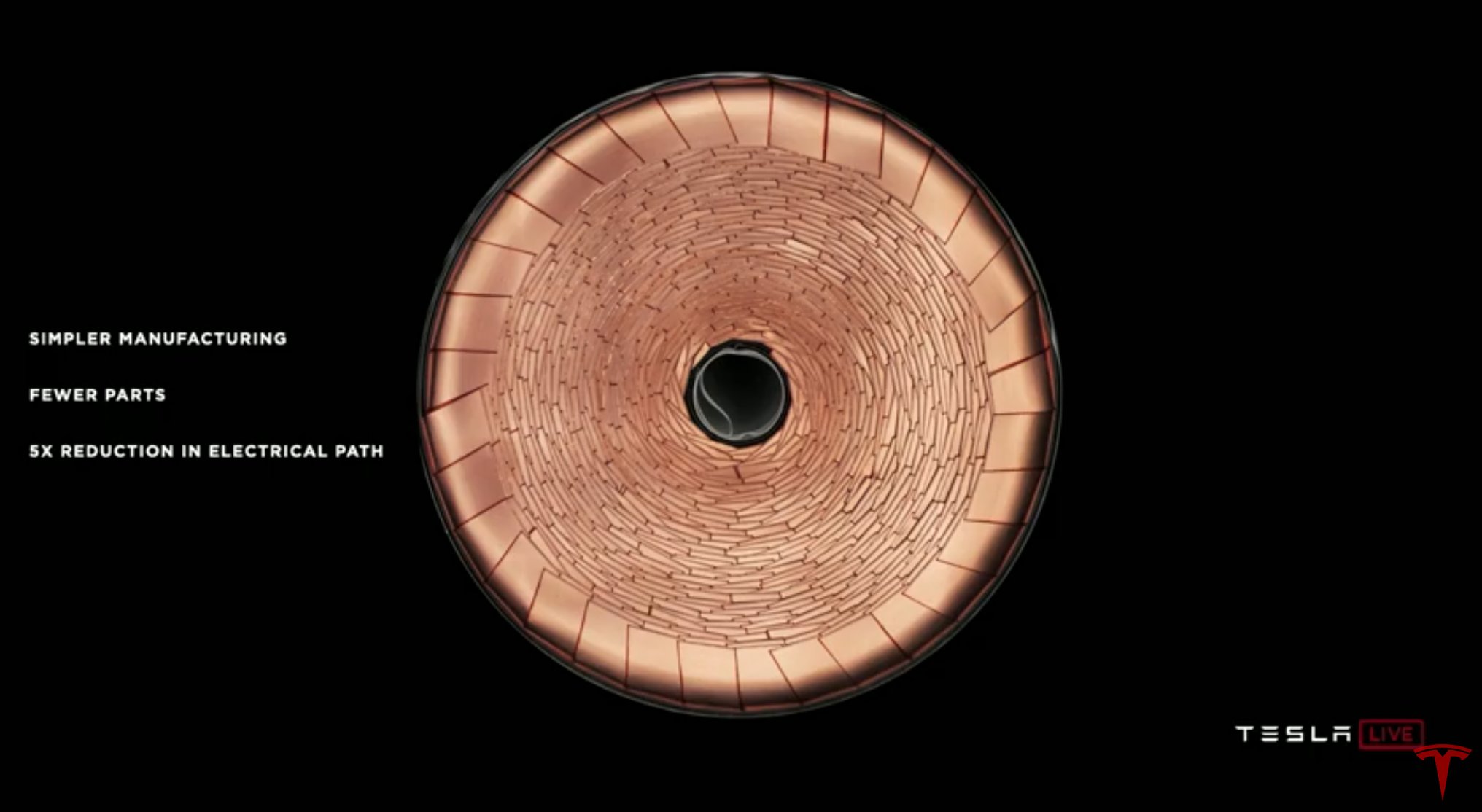

As has been anticipated a lot in recent days: a new “tabless” cylindrical cell with a relatively chunky 46 mm diameter (compared to 21 mm they’re using now).

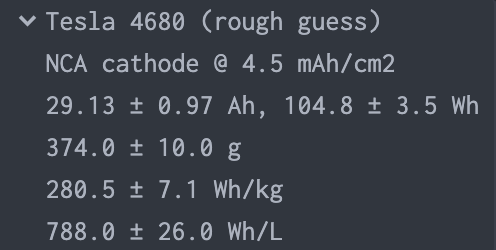

At a rough guess this is probably going to be about a 25-30 Ah cell with perhaps >280 Wh/kg (compared with ~4.8 Ah and ~250 Wh/kg now)

(more detailed rough guess on the new 4680 form factor)

Dry electrodes: very promising for a more efficient process overall, but sounds like lots of problems still to work out!

Now onto the topic of Si anodes, which I was not really expecting. Making the point that most other existing approaches are highly engineered materials, instead talk about raw metallurgical silicon with a polymer mixed in to handle the expansion. But not a lot of details here…

The big takeaway from this is how much further Tesla expect costs to be cut, performance improved and production speed to be increased from engineering improvements. Besides Si there’s not been much to talk about in terms of cell chemistry.

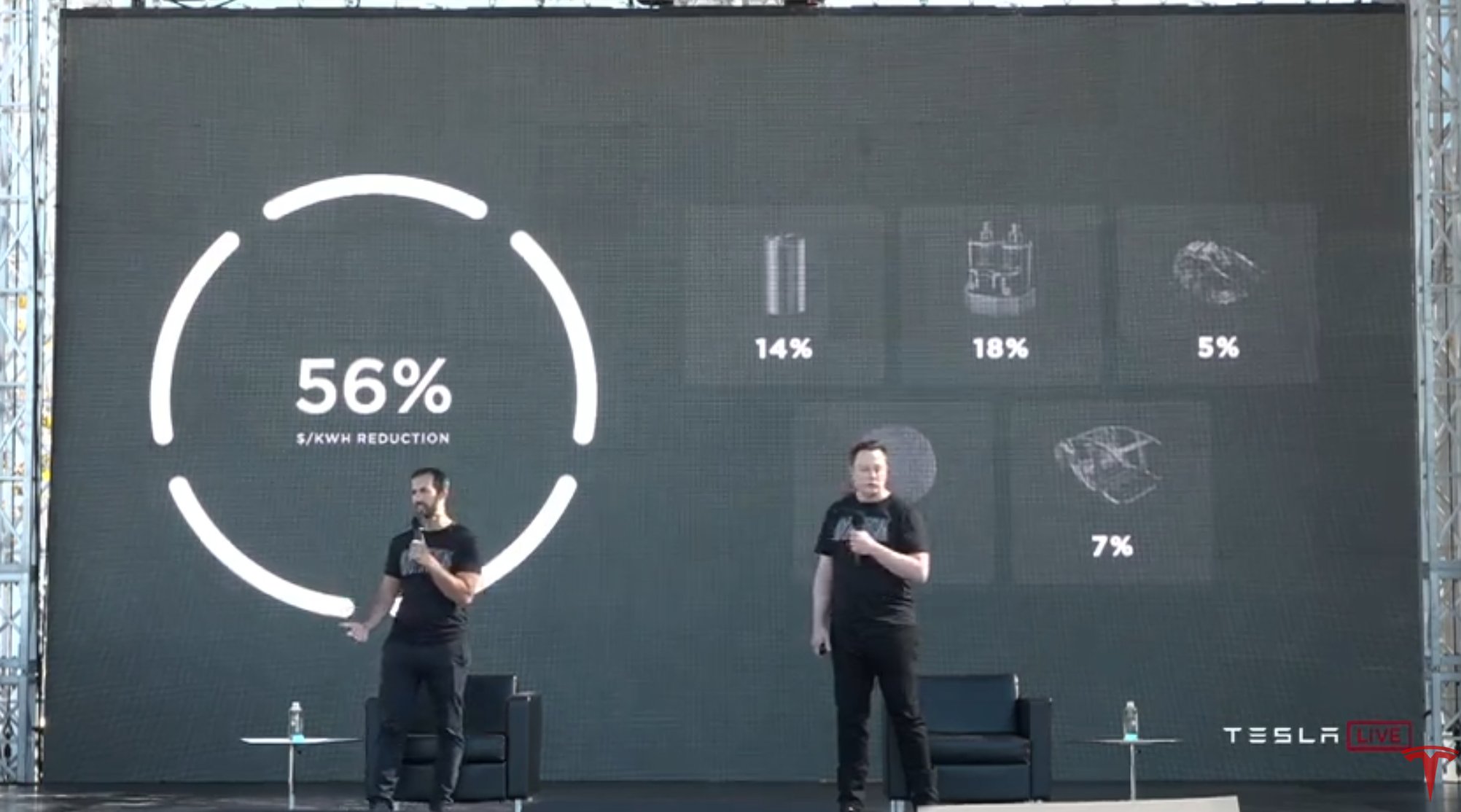

Case in point - new form factor expected to give 14% cost reduction, but a mooted new high-silicon electrode made by a cheap process (presumably cutting materials use and boosting energy density) is only 5%

And that’s a wrap. Plenty more to talk about than what I highlighted, but there’ll be plenty of writeups on this for sure. Regardless of whether Tesla will meet their lofty goals in coming years it was at least a showcase of what can still be done, esp. on manufacturing side

So after a little sleep I can digest some of yesterday’s presentation a little more. When I was asked before about what I thought would be presented I said I didn’t expect anything radically new in terms of chemistry, and that (not very bold) prediction was true at least…

And though manufacturing processes were front and centre there was not much about e.g. the products for the new cells, it seemed more like presenting their vision for their own manufacturing. @hanseric puts it better.

Since my interest comes from the chemistry side of things, for me there was a good reminder that there’s plenty of room left in Li-ion chemistry not only to squeeze out more performance but most importantly cut cost.

What cell chemistry was there was left quite vague, such as talk about a new process for Si anodes which I (and others) take with a large pinch of salt. No mention that I noticed about a million mile battery either.

The scale of their ambitions (TWh scale, 20 million cars/year etc) is enormous and there are obviously going to be plenty of questions and arguments about this (I have my own too). But the direction of travel is increasingly clear, and they have everybody’s attention.